What is PCB Tab?

- afax TE.

- Aug 12, 2024

- 2 min read

A PCB tab refers to a small extension or "tab" of the printed circuit board (PCB) that is used during the manufacturing process, primarily for handling and mounting purposes. These tabs are designed to be removed once the board assembly is complete, leaving the finished PCB in its desired shape.

Key Aspects of PCB Tabs

Purpose and Functionality:

Handling: During the assembly process, especially when using automated equipment like pick-and-place machines, tabs provide a convenient area for gripping or securing the PCB. This is particularly useful for smaller or irregularly shaped boards that may be difficult to handle without additional support.

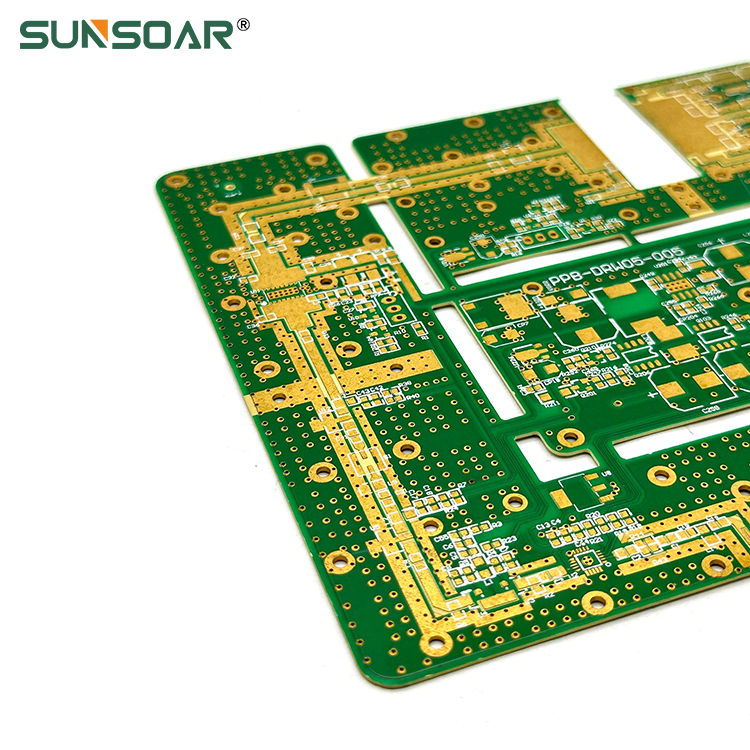

Panelization: In cases where multiple PCBs are manufactured together on a single panel, tabs are used to connect individual boards. This panelization allows for easier processing and handling during manufacturing. The tabs keep the boards together until the final separation step.

Routing and Separation: After assembly, the tabs are either routed out (cut) or snapped off, separating the individual PCBs from the panel.

Types of PCB Tabs:

V-Scored Tabs: These tabs are partially cut with a V-groove, making them easy to snap off manually or with minimal force after the assembly process. V-scoring is typically used for straight-line separations.

Routed Tabs: These tabs are connected to the PCB with small breakaway sections (often referred to as "mouse bites"). After assembly, the routed tabs are removed, either by breaking them off or by using a depaneling tool.

Non-Plated Tabs: Sometimes, tabs are intentionally left without any copper plating or circuitry to ensure they do not interfere with the board’s electrical performance or functionality.

Considerations in Design:

Tab Location: The placement of tabs is crucial. They are usually positioned on non-critical areas of the PCB to avoid affecting the functionality or aesthetics of the final product.

Tab Size: The size of the tabs must be sufficient to provide stability during handling but small enough to be easily removed without damaging the board.

Advantages of Using PCB Tabs:

Enhanced Stability: Tabs help maintain the structural integrity of the PCB during manufacturing, especially for smaller or more delicate designs.

Efficiency in Mass Production: Panelization with tabs streamlines the manufacturing process, allowing multiple boards to be processed simultaneously, which reduces costs and time.

Conclusion

PCB tabs are an essential feature in PCB manufacturing, aiding in the handling, processing, and separation of individual boards. They contribute to the efficiency and effectiveness of the production process, ensuring that each PCB is manufactured to high standards while being easy to manage during assembly. Once their purpose is served, these tabs are removed, leaving the final PCB ready for use in electronic devices.

Opmerkingen