Basic Things You Should Know About PCB Assembly Process

- afax TE.

- Aug 14, 2024

- 2 min read

Basic Things You Should Know About PCB Assembly Process

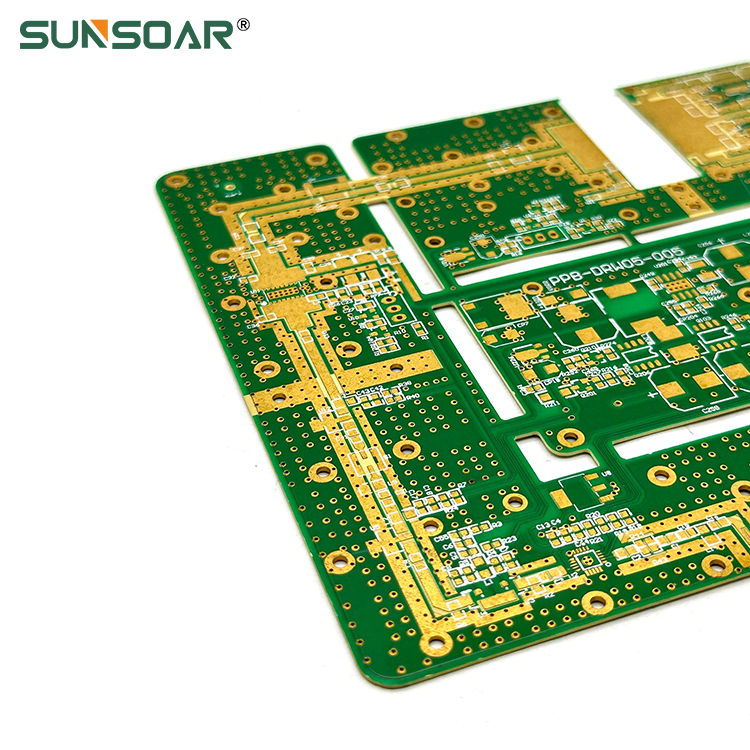

The Printed Circuit Board (PCB) assembly process is a crucial step in creating electronic devices, as it involves placing and soldering various electronic components onto a PCB to create a functional electronic circuit. Understanding the basics of PCB assembly is essential for anyone working in electronics, whether you are a designer, engineer, or manufacturer.

1. Surface Mount Technology (SMT)

SMT is the most common method used in PCB assembly today. In this process, components are mounted directly onto the surface of the PCB. The components used in SMT are much smaller than those used in older methods, allowing for more compact and efficient designs. The process begins with applying solder paste to the PCB, followed by placing the components using a pick-and-place machine, and finally soldering the components in place through a reflow oven.

2. Through-Hole Technology (THT)

Though less common today, THT is still used in situations where components need to be more securely attached to the board, such as in high-stress environments. In THT, components are inserted into pre-drilled holes on the PCB and soldered manually or using wave soldering. This method provides stronger mechanical bonds and is often used alongside SMT for specific components.

3. Soldering Methods

The soldering process is critical in PCB assembly. There are two main methods: Reflow Soldering and Wave Soldering. Reflow soldering is used in SMT, where the entire PCB is heated to melt the solder paste and create connections. Wave soldering is used in THT, where the PCB is passed over a wave of molten solder to solder the component leads.

4. Quality Control and Testing

After assembly, PCBs must undergo rigorous testing to ensure they function correctly. Common tests include Automated Optical Inspection (AOI), where cameras scan the board for defects, and In-Circuit Testing (ICT), which checks the electrical performance of the board. Functional testing may also be performed to simulate real-world operation and ensure reliability.

#PCBAssembly #ElectronicsManufacturing #SurfaceMountTechnology #ThroughHoleTechnology #PCBDesign #SolderingProcess #QualityControl #PCBSun

5. Importance of PCB Design

Good PCB design is crucial for a successful assembly process. The design should account for the placement of components, thermal management, and ease of testing. A well-designed PCB can reduce the chances of errors during assembly and improve the overall performance of the final product.

Understanding these basic aspects of PCB assembly will help you appreciate the complexity and precision involved in creating modern electronic devices. Whether you're involved in the design, production, or just interested in electronics, knowing the essentials of PCB assembly is foundational knowledge.

For more detailed insights into PCB manufacturing and assembly, visit our website at pcbsun.com or check out our YouTube channel Sunsoar PCB.

Comments