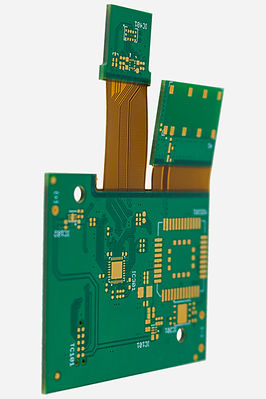

Rigid Flex PCB Manufacturing Service

Discover SUNSOAR exceptional capabilities in rigid-flex PCB manufacturing:

-

Rigid Boards: Up to 20 layers, accommodating buried or blind hole designs.

-

Flex Boards: Up to 8 layers, supporting PI, Aluminum, FR4 stiffener, and other specialized material requirements.

Get Your Quote Today! Send your PCB files to sales03@sunsoartech.com for a prompt quotation.

SUNSOAR rigid-flex PCB solutions are tailored for leading electronic industries. Engineered with rigorous quality control and reliability standards, our boards excel in demanding applications such as aerospace, robotics, medical, and military sectors.

Enhanced Performance, Cost Efficiency: Rigid-flex circuits serve as dependable alternatives to traditional wire harness assemblies, offering substantial cost savings without compromising performance.

Comprehensive Support: Count on our expert PCB engineers to guide you from initial rigid-flex design phases to final production, ensuring your flex and rigid-flex circuit needs are met with precision and excellence.

Introduction

A rigid-flex printed circuit board (PCB) integrates rigid and flexible substrate materials, combining mechanical support and component mounting with the ability to bend and flex. This unique construction supports complex interconnections and 3D form factors, making it ideal for diverse applications across industries.

Key Aspects of Rigid-Flex PCBs:

Rigid sections provide robust mechanical support and component mounting, enhancing structural integrity. Flexible sections enable dynamic connections between rigid areas, facilitating bending, folding, and conforming to spatial constraints. Applications:

Rigid-flex PCBs are pivotal in consumer electronics, automotive systems, aerospace technology, medical devices, and industrial equipment. In-Depth Exploration:

This article delves into the intricacies of rigid-flex PCB technology, encompassing:

-

Definition and operational principles

-

Design essentials and considerations

-

Manufacturing methodologies

-

Cost determinants

-

Application scenarios and industry benefits

-

Comparative advantages over traditional PCBs

-

Practical guidelines for efficient design and implementation

Understanding rigid-flex PCBs empowers designers and engineers to harness their capabilities effectively, enabling innovative solutions that demand flexibility, compactness, and intricate geometries.

What is Rigid Flex PCB?

Rigid-flex PCBs combine rigid and flexible PCB materials interconnected through flexible adhesive layers. Rigid sections, typically FR-4, offer robust mechanical support for components, while flexible sections, using materials like polyimide, enable dynamic movement and shaping.

Key Features:

-

Mechanical Integrity: Rigid sections support component mounting, while flexible sections facilitate dynamic movement and shaping.

-

Materials: FR-4 for rigid sections, polyimide or flexible dielectrics for flexible sections, bonded with advanced adhesion techniques.

-

Signal Routing: Conductive traces etched on both rigid and flexible layers connect components via plated vias and holes.

-

Flexibility: Enables dynamic bending, folding, and complex 3D shapes.

-

Integration: Reduces weight and space by eliminating wires and connectors.

-

Reliability: Enhances ruggedness with flex-resistant cabling.

-

Cost Efficiency: Lowers assembly costs by integrating multiple PCBs.

Applications: Ideal for compact, dense electronics in consumer electronics, automotive, aerospace, medical devices, and industrial equipment.

Rigid-flex PCB technology offers a versatile, integrated solution compared to discrete PCBs and external cabling, enhancing design flexibility, performance, and reliability across a range of demanding applications.

How Does Rigid Flex PCB Work?

Rigid-flex PCBs seamlessly integrate rigid and flexible board materials, such as FR-4 and polyimide, respectively, enabling dynamic flexibility and robust mechanical support. Here’s an overview of how this innovative technology operates:

Structural Integration:

-

Rigid segments provide structural support for component mounting and efficient heat dissipation.

-

Flexible segments allow for out-of-plane interconnections between rigid sections, accommodating dynamic movements.

Functional Design:

-

Conductive layers are meticulously etched onto both rigid and flexible substrates, facilitating signal routing.

-

Plated through holes establish vertical connections across all PCB layers, ensuring comprehensive electrical connectivity.

Component Mounting:

-

Components are exclusively mounted on rigid portions, optimizing stability and reliability.

-

Flexible sections enable intricate folding, bending, and shaping, adapting to diverse spatial requirements.

Versatile Applications:

-

Rigid-flex PCBs are adeptly contoured into 3D geometries, supporting innovative design concepts across industries.

Integration Process:

-

Advanced lamination processes securely bond rigid and flexible materials into a cohesive PCB unit.

-

Robust adhesion techniques endure thermal and mechanical stresses, guaranteeing operational resilience.

Design Considerations:

-

Thoughtful trace routing on flexible layers accommodates dynamic bending without compromising performance.

-

Mitigating stress at rigid-to-flex transitions and maintaining precise bend radius control ensures operational longevity.

-

Seamless thickness transitions between rigid and flexible areas enhance overall flexibility and functionality.

Properly engineered, rigid-flex PCBs achieve unparalleled flexibility and 3D adaptability while preserving signal integrity and power efficiency.

Rigid Flex PCB Design Considerations

Designing a reliable rigid-flex PCB demands meticulous attention to unique considerations that differentiate it from standard rigid PCBs. Here's an enhanced overview of key design considerations for rigid-flex PCBs:

1. Layer Stackup The layer stackup must be carefully planned to balance the needs of rigid and flexible sections. Rigid layers typically use materials like FR-4 for structural support, while flexible layers employ polyimide or similar materials for dynamic flexibility. Adhesive layers bond these materials into a cohesive unit, impacting flexibility, thickness, impedance control, and manufacturability.

2. Rigid-to-Flex Transitions Managing transitions between rigid and flexible sections is critical to prevent stress-induced issues such as cracking or delamination. Design strategies include gradual transition geometries, wider annular rings to reduce stress, minimizing exposed copper near transitions, and avoiding sharp angles in favor of smoothly curved corners.

3. Bend Radius Flexible segments must be designed with a minimum bend radius to avoid damaging copper traces or layers. Factors influencing bend radius include material properties, layer stackup, copper thickness, and dynamic flexing requirements. Typical bend radius values range from 3mm to 10mm depending on these factors.

4. Component Placement Components are mounted exclusively on rigid sections due to the inability of flexible layers to support them. Careful placement considerations include creating keepout zones around the edges of rigid areas to prevent component leads from overlapping into flexible sections. High-stress components and those requiring thermal management should be strategically located away from rigid-flex transitions, ensuring adequate heat dissipation through sufficient copper areas.

5. Routing Considerations Routing on flexible layers necessitates adjustments such as wider trace widths and spacing to endure dynamic bending without compromising integrity. Avoiding acute angles, routing along neutral bend axes where feasible, and maintaining balanced copper density across flexible layers are crucial for reliable performance.

By adhering to these specialized design guidelines, engineers can optimize rigid-flex PCB layouts for enhanced durability, flexibility, and performance across a wide range of applications.

Rigid Flex PCB Manufacturing Process

Producing a reliable rigid-flex PCB requires advanced manufacturing techniques and processes. Here is an overview of rigid-flex fabrication:

1. Materials Preparation

The process starts with raw rigid and flexible core materials being prepared. The materials are cleaned, coated, and conditioned to optimize adhesion and processing performance.

2. Imaging

The individual inner and outer layers are imaged with the conductive pattern using lithography and etching processes. This forms the traces, pads, and features on each layer.

3. Hole Formation

Holes are drilled or punched through the core layers. This includes component holes, tooling holes, and through vias between layers. The holes are plated with copper to form the vertical interconnects.

4. Lamination

The rigid and flexible core layers are precisely aligned and bonded using high temperature and pressure. The bond line between materials is critical to performance. Advanced adhesives are used.

5. Outer Layer Imaging

After lamination, the outer layer traces and features are imaged using lithography and etching. This completes the conductive patterning on the PCB.

6. Solder Mask and Finish

Solder mask is applied to exposed copper surfaces. The edges of pads and traces are exposed. The PCB surface is finished with treatments like ENIG, immersion tin, or OSP.

7. Singulation

The large panel is precision routed to separate into individual PCBs. Rigid-flex PCBs often have complex board shapes.

8. Testing

Each completed PCB goes through electrical testing and inspection to verify function and workmanship. Automated optical inspection checks feature accuracy.

9. Assembly

Components are mounted on the rigid portions using soldering or adhesive attachment. The PCB can then be dynamically flexed into the 3D shape as required.

Rigid-flex PCB fabrication requires expertise in advanced processes like:

-

Surface preparation and adhesion promotion

-

High-accuracy imaging and pattern transfer

-

Controlled lamination of dissimilar materials

-

Mitigation of thermal and mechanical process stresses

-

Precise techniques for routing, drilling, and hole plating

-

DFM techniques for optimizing manufacturability

Rigid Flex PCB Cost Factors

Here is a detailed analysis of the key factors that influence the cost of rigid-flex PCBs. These PCBs typically incur higher costs than standard rigid PCBs due to the use of specialized materials, complex processes, and lower production volumes:

1. Layer Count The cost increases significantly with the addition of more conductive layers due to the increased material requirements, lamination complexity, and fabrication difficulty. High layer count rigid-flex PCBs are exponentially more expensive than simpler 2-4 layer versions.

2. Panel Utilization Rigid-flex PCB panels often exhibit lower utilization rates due to their intricate geometries, leading to higher costs. Optimal panel layout and utilization are crucial for cost efficiency.

3. Finishing and Coatings Specialized solder masks, coverlays, and surface finishes add to the cost compared to standard FR-4 finishes. Techniques like thick copper plating and buried vias further escalate expenses.

4. Flexible Material Type The choice of flexible dielectric materials, such as polyimide, LCP (Liquid Crystal Polymer), or PEN (Polyethylene Naphthalate), influences the cost. More durable and heat-resistant materials tend to be more expensive.

5. Registration Accuracy Achieving precise alignment of layers and high drilling/routing accuracy adds to the cost. Tighter tolerances necessitate advanced equipment and sophisticated processes.

6. Design Complexity Complex routing, high component density, HDI (High-Density Interconnect) features, and impedance control requirements increase fabrication difficulty and costs.

7. Low Volume Production The relatively smaller market for rigid-flex PCBs prevents the realization of economies of scale. Consequently, shorter production runs lead to higher per-unit costs.

8. Testing and Inspection Extensive inspection and electrical testing are required to ensure the quality of rigid-flex PCBs, adding to the overall cost compared to basic PCB validation processes.

In addition to fabrication costs, there are significant engineering costs associated with the specialized design, simulation, prototyping, documentation, and qualification of rigid-flex PCBs. These costs reflect the advanced expertise and precision required to produce reliable and high-performing rigid-flex PCB assemblies.

Rigid Flex PCB Applications

Here are some of the major application areas taking advantage of rigid-flex PCB technology:

Consumer Electronics

Wearables, smartphones, laptops, tablets, cameras, and other connected consumer gadgets utilize rigid-flex PCBs to achieve folding, compact size, rugged cabling, and dynamic positioning.

Automotive Electronics

Automotive camera systems, powertrain electronics, LED lighting, and in-vehicle infotainment systems employ rigid-flex PCBs for shape conformability and vibration resistance.

Medical Equipment

Hearing aids, blood analyzers, surgical tools, and implants use rigid-flex PCBs to fit within tight, curved spaces and provide dynamic interconnections.

Industrial

Industrial rigid-flex applications include robotics, motion control, telemetry devices, and navigation systems that require ruggedized, shape-conforming PCBs.

Military/Aerospace

Avionics systems, guidance controls, communications, and navigation electronics in defense and aerospace applications utilize rigid-flex PCBs for compact, rugged performance.

Advanced HDI

Rigid-flex PCBs are commonly used as integrated carrier boards for ultra-high density interposers and multi-chip modules (MCMs) for applications like ASIC packaging.

From small wearable gadgets to large avionics systems, rigid-flex PCB technology enables solutions not possible with standard rigid boards – supporting dynamic motion, flexing, wrapping, and 3D shaping.

Advantages vs Standard PCBs

Here are some of the key benefits provided by rigid-flex PCBs compared to traditional rigid PCBs:

Dynamic Flexing and Motion

The flexible portions of rigid-flex PCBs enable motion, vibration absorption, twisting, bending, and wrapping unavailable with rigid PCBs.

Lightweight and Compact

By eliminating external cables and connectors, rigid-flex PCBs achieve significant size and weight reduction for portable and space-constrained designs.

Enhanced Reliability

The integrated rigid-flex structure avoids interconnection failures associated with cables and connectors. System reliability improves.

Complex Shaping

Conformal and complex 3D shapes can be achieved with rigid-flex PCBs to fit product enclosures and mechanics. Rigid PCBs are planar and 2D.

Simplified Assembly

Components can be pre-mounted on the rigid portions, enabling system assembly by simply folding the rigid-flex PCB into shape.

Design Flexibility

Rigid-flex PCBs allow optimal placement of rigid areas only where mechanically required, improving design flexibility.

Cost Savings

By reducing parts count, assembly steps, and handling, rigid-flex PCBs can achieve net cost savings compared to hybrid rigid/flex solutions.

For applications requiring dynamic motion, vibration resistance, light weight, or complex 3D assembly, rigid-flex PCB technology provides performance and reliability benefits over traditional rigid PCBs. The advanced integration reduces cost and complexity compared to hybrid solutions.

Design Guidelines and Best Practices

Here are some key design guidelines and best practices to follow when working with rigid-flex PCBs:

Manage Layer Stackup Carefully

-

Use sufficient layers and thickness for rigidity, heat dissipation, and signal integrity.

-

Minimize flexible layers to what’s required for dynamic bending motions.

-

Balance properties like impedance control, flex/rigid transition stresses, and manufacturability.

Optimize Rigid-Flex Transitions

-

Use gradual tapers and teardrop shapes at transitions.

-

Keep components and vias back from transition intersections.

-

Adjust solder mask pullbacks methodically.

-

Analyze transition points using FEA stress simulation.

Maintain Proper Bend Radius

-

Do not exceed minimum bend radius specifications.

-

Keep bends in the central neutral axis of flex layers where possible.

-

Dynamic flexing stresses can decrease bend radius over product lifetime.

Follow Flexible PCB Design Rules

-

Use wider trace/space dimensions on flex layers.

-

Avoid acute angles on traces and planes.

-

Balance copper density across flex layers.

-

Route critical signals near neutral bend axis.

Allow Adequate Board Tolerances

-

Account for greater alignment variability between layers.

-

Provide tolerance for dynamic shape variations during use.

-

Ensure critical features have design margin.

Simulate PCB Performance

-

Verify shape and motion with 3D CAD simulation.

-

Perform stress analysis at rigid-flex transitions.

-

Thermally modelComponents on rigid areas with sufficient copper.

-

Verify signal integrity, especially across bends.

Facilitate Manufacturing and Testing

-

Use standard materials when possible.

-

Account forthickness variations between rigid and flex areas.

-

Provide testpoints to access critical signals.

-

Follow fabrication shop DFM guidelines.

With attention to these design principles, rigid-flex PCBs can be optimized to achieve the desired balance of dynamic flexing, shapeability, reliability, and manufacturability.

Rigid Flex PCB Design Software Tools

To facilitate working with rigid-flex PCB designs, engineers use various software tools for tasks like:

PCB Layout

-

Altium Designer

-

Cadence Allegro

-

Mentor Xpedition

-

Zuken CR-8000

3D Modeling

-

Cadence OrCAD 3D Modeler

-

Altium 3D PCB Visualization

-

SolidWorks PCB 3D Modeling

Simulation and Analysis

-

Ansys Q3D Extractor (for signal integrity)

-

Ansys HFSSTM (for antenna design)

-

Cadence Clarity 3D Solver (for thermal and mechanical analysis)

-

Mentor Valor Process Preparation (for manufacturability verification)

Documentation

-

AutoCAD

-

PDF 3D

-

Illustration and diagramming tools

Using these sophisticated design automation tools enables engineers to design and analyze complex rigid-flex PCBs with confidence. The tools help optimize parameters like layer stackup, trace routing, 3D shape modeling, signal and power integrity analysis, thermal analysis, and manufacturability validation.

Conclusion and Summary Points

-

Material Composition: Rigid-flex PCBs integrate rigid board materials, such as FR-4, with flexible dielectric materials, such as polyimide, enabling dynamic flexing and 3D shaping capabilities.

-

Design Considerations: Meticulous design is crucial to effectively manage parameters like layer stackup, rigid-to-flex transition geometry, bend radius, trace routing, and component placement.

-

Structural and Functional Benefits: Rigid sections offer mechanical support while flexible sections facilitate out-of-plane interconnections, enhancing the overall functionality.

-

Performance Advantages: Rigid-flex PCBs provide significant benefits in terms of space savings, weight reduction, complexity management, and reliability compared to traditional PCBs.

-

Cost Implications: Although more expensive than rigid PCBs, the cost can be justified by advantages in system miniaturization, component consolidation, and streamlined assembly processes.

-

Application Areas: Key industries utilizing rigid-flex PCBs include consumer electronics, automotive, aerospace/defense, medical devices, and industrial automation.

-

Design Guidelines: Adherence to best practices for flex/rigid transitions, bend radius control, trace routing, and thorough modeling ensures reliable and long-lasting performance.

-

Unique Benefits: Rigid-flex PCB technology offers unparalleled advantages for products requiring dynamic flexing, vibration resistance, lightweight construction, and conformal assembly. Understanding the intricate design, manufacturing, and cost considerations enables engineers to effectively leverage rigid-flex PCBs for innovative solutions.